Gatan Arrival Brings Focus to Hacienda

Gatan Arrival Brings Focus to Hacienda

Company Makes Peripheral Equipment for Electron Microscopes

Gatan Inc., a manufacturer of equipment and software used in electron microscopy, moved into facilities at 5933 Coronado Lane on November 1. The company, which currently employs 47 people, occupies the entire 19,734 square foot facility.

"This building was too good to pass up," says Don Templeman, Gatan's president and CEO. "It's the right size, the right configuration, and just really fit well with our plans."

The building will serve as the corporate headquarters and central location for research and development. The company also maintains national sales offices in Germany, the United Kingdom, Tokyo, and Hong Kong, as well as its manufacturing facilities north of Pittsburgh, Pennsylvania.

A History of Growth

Gatan was founded in Pittsburgh, Pennsylvania, as a spin-off from a contract machine shop after determining there was a market for specimen holders for electron microscopes.

"Specimen holders have to be very, very precise. To an electron microscope, a vibration of a millionth of an inch moves the specimen completely in and out of the field of view," explains Templeman. "It has to be very stable, both mechanically and thermally."

The behavior of matter at a molecular scale, as is viewed by an electron microscope, creates a number of unusual engineering problems which Gatan has solved in their full line of products.

For instance, Gatan's specimen holders maintain the stability of the viewed object, but also offer controlled movement.

"We specialize in specimen holders that allow you to tilt and rotate the sample, but still hold it within a few nanometers," says Templeman. "We also make holders called cryo-holders or cooling holders that use liquid nitrogen to cool samples, heating holders that can go up to 1,000 degrees centigrade so you can look at thermal effects while you're viewing an object, and straining holders that allow you to put the sample under strain so you can look at those effects."

Electron Microscope Digital Imaging

One of the biggest innovations in electron microscopy over the last several years is the use of digital imaging technologies to allow real-time viewing of specimens.

"Traditionally, you would have had to use a camera with film that would have to be developed and printed before you could see the image," says Templeman.

To a layman, it sounds almost like taking an x-ray: you point the machinery and shoot, then develop the film to see if you finish with the picture you had hoped for.

"Using traditional methods, usually you would take 20 or 30 images just to make sure you get the one you want, develop it, and then digitize it so that you can run tests on it," says Templeman. "This can take hours or sometimes days.

"We have a line of cameras that produces digital images, so you see everything in real time," he says. "With our products, you can take an image and you can immediately process it."

Gatan's Digital Micrograph software gives users a full image processing suite, including microscope control and post processing of images, including stitching together or compositing photos of adjacent areas.

"Compositing photos is much more efficient with a digital format," says Templeman. "Even at very high magnifications, you can't tell where the seams are."

Used All Over the World

Gatan's products are used at some of the best known scientific and research facilities in the world, including the Oak Ridge National Laboratory and the National Center for Electron Microscopy at the Lawrence Berkeley Lab.

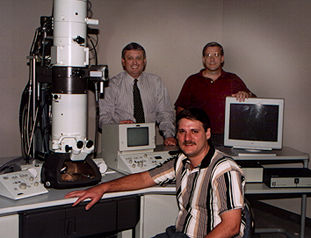

Photo: Don Templeman, president and CEO, front, and Dr. Thomas Connelly (left) and Dr. Vance Nau of Gatan with one of the three electron microscopes in their Hacienda facility.

Also in this issue...

- Gatan Arrival Brings Focus to Hacienda

- Wanted: Toy Testers - Duties Include Having Fun

- Business Bits

- Hacienda, Other Area Parks to Participate in Holiday Food Drive

- Pleasanton Partnerships in Education Popular with Area CEO's

- Office Furniture Ergonomics a Key Component, Says Space Designs

- City Offers Unique Canvas Bags to Promote Shopping in Pleasanton